Q4 2020

Isabellenhütte Newsletter Alloys

Ladies and gentlemen and colleagues,

As usual, we would like to inform you in our semi-annual newsletter about the current situation and developments in Isabellenhütte's Alloys business unit (BU-LE).

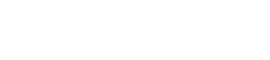

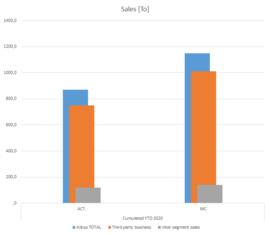

An extraordinary year is nearly behind us. An unprecedented crisis for Isabellenhütte's Alloy division led to a decline in incoming orders of up to 60% compared to the same months of the previous year. At the beginning of the COVID-19 pandemic, many of our customers were still replenishing their stocks to secure their supply chain. Then from April on we had a 6-month buyer's stoppage. Based on the information available from the market, we had forecast an improvement in the situation for the period between mid-September and mid-October. Since the second week of October, we have indeed seen a sharp rise in incoming orders with a daily peak of 27.5 tons on October 23, 2020. As far as I know, this value is a daily record in the history of alloys and is about as high as the total order intake in August. We are currently hopeful with regard to incoming orders. However, this trend is still fragile due to the global situation.

In general, our sales volume and revenue are very much behind the management case prepared in the fall of 2019. We were only able to sell more than planned in March.

Outlook for 2021

The economy is currently picking up in the alloys sector and with it the order intake is increasing as well. The predicted scenario is entering into force. It is certainly too early to give the all-clear, but there are increasing signs of better capacity utilization at our plant.

Nevertheless, the given uncertainty of the markets and the resulting highly volatile situation requires a high degree of flexibility from all parties involved.

As in my last informational letter, I would like to address the positive aspect of winning back customers again today. We are increasingly convincing customers with our performance geared to their requirements. Let us continue to work together to live this customer orientation or "customer centricity" / "customer excellence."

Outlook for regional markets:

- Asia: Asia has shown increasing demand since the middle of the year. However, the market to be addressed in Asia for Isabellenhütte alloys is manageable due to our price structure.

- Americas: The US is still a positive exception. We are seeing strong turnover and sales figures over the whole year. The COVID-19 situation in the USA and the presidential election had almost no influence on the high purchasing level of our products. However, there are still fears that an extension of the pandemic could lead to plant closures and, in turn, to a slump in sales.

- Southwestern Europe: Italy, France and Switzerland are also showing a reawakening demand, which has been expressed, for example, by 2 major orders from customers in Italy and Switzerland. However, it is to be feared that economic performance will be affected by the recent lock-downs.

- Germany, Northern and Eastern Europe: Here, demand is still lagging behind developments in Asia, the USA and Southern Europe.

Activities from the 2020 targets

We have used the crisis period caused by the COVID-19 pandemic to drive forward the reorganization of the Alloys business unit.

I would like to give you a few more examples:

- Rolling mill: In one project, we conducted a detailed economic analysis of our rolling mill. The aim of the project was to decide whether to continue to operate our rolling mill or scrap it. All economic and technical aspects were taken into account. The result: The rolling mill will be scrapped or sold (currently not yet decided) and will therefore not be put back into operation. Several utilization concepts for the rolling mill hall were and are being developed. A final decision on this is still pending.

- Multi-project management: The supervision of the Alloys business unit projects by Mr. Eysert has very quickly led to successes in the processing of various projects. Examples include:

- Production planning (Mr. Benfer; optimization of production planning on all planning levels)

- Process standard variants (T. Busch; definition, production and inventory control of standard stock materials to meet the needs of our customers faster)

- Cost determination for rework (B. Lorenz; analysis of the costs arising from unplanned rework)

- Operational level agreement / OLA; (F. Fine; Establishment of binding guidelines and reaction times in internal procedures and processes)

- Standardization of thermal qualities (D. Benfer; Standardization and reduction of thermal materials for complexity and cost reduction)

This enabled us to complete nine A and B level projects.

- Shop Floor Management (SFM): The limitations caused by COVID-19 have led to a delay in the implementation. But in the meantime, we have found a mode in which SFM can be lived.

- Shop Floor in sales and KA. The two departments Sales and KA are the first administrative departments of Isabellenhütte that have introduced and applied SFM.

- PDCA-Thermo: The goal was to halve the failure rate of thermal orders of 12%. Through a variety of measures, starting in the melting shop, through the TC and DE, a value of approx. 4% failure rate was achieved on average. This immediately leads to cost reduction.

- Reorganization of the sales structure: The reorganization of sales territory responsibility and the organization of global sales, which was initiated in the previous year, was completed in 2020. New responsibilities have been assigned to European sales. Since January, all business for South, Central and North America has been the responsibility of the colleagues of Isabellenhütte USA (ISAUSA). Japan is assigned to the branch office in Japan (IHKK) and Asia (except Japan) is supported by the colleagues of the sales subsidiary in Shanghai (IHCN).

- Pot annealer: The new pot annealer, currently in the development process at the company IHU, comprises an investment of approx. € 850,000. The system will be installed in the rolling mill (former water cellar) in Q1/Q2 2021

- Over all, € 1.4 million were invested in the Alloys business unit equipment and systems in 2020.

Goals for 2021

As the Alloys business unit, we have set ourselves new goals for 2021. In addition to the positive earnings to be generated, we will focus more on the topics of customer satisfaction, product cost reduction and future orientation of the Alloys business unit next year.

I already mentioned the topic of customer satisfaction above under the heading of Customer Excellence. The self-image of always inspiring our customers under all economic conditions will determine our daily actions.

Product cost reduction is necessary in order to remain competitive in the market. We are in daily competition with globally operating companies. In the past years we have laid many foundations in the field of lean management, standardization and personal responsibility. We will continue to advance these in 2021 and, wherever possible, implement them in the final stages.

Future orientation is a broad field. This includes not only the points already described above, but also explicitly the development of new products and business ideas. Among other things, innovation management was also implemented this year. All efforts in this direction and thus also in the future viability of the Alloys business unit and Hütte in general sink or swim with all of our ideas. We have centralized the management and exploitation of all ideas on the topic in the person of Mr. Michael Sting in the role of Business Development.

I would like to thank you all for your cooperation, understanding, flexibility and dedication in what will hopefully turn out to be unique times. I wish you and your families a Merry Christmas and a good start to the new and hopefully different year.

I wish you good luck and good health to you and your families.

Jens Hartmann

Leader Global Business Unit Alloys

Executive Vice President

Innovation Projects in Alloys

Alloy engineering & temperature control modules for medical engineering

As already reported elsewhere, we are currently implementing a new innovation process for Isabellenhütte. The aim of this process is to continuously identify unsolved problems, so-called "pain points," in contact with our customers and to develop suitable solutions. The decisive factor here is that this process begins with customer dialog and not with a technical idea. In addition, the problem to be solved should not be limited to a single customer, but should be applicable to many customers. Possible solution concepts will only be developed in a second step and then evaluated in terms of technical and commercial feasibility. In July of this year, the first two innovation projects in the new innovation process were selected in a new format, the so-called "Base Camp for Innovation."

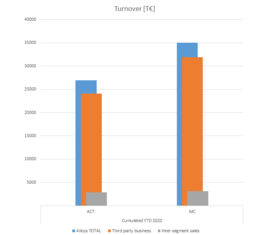

The project "Temperature Control in Medical Engineering" deals with the provision of precise temperature control in medical engineering applications. This topic was motivated by a technology that became known in connection with the current pandemic: PCR cyclers are devices that provide an important process step for the detection of DNA material (such as viruses). The genetic material of the viruses to be detected in a smear test is often only present in very low concentrations. Therefore, the DNA substance must first be amplified in order for it to be detectable at all. A PCR cycler runs through a very precisely defined temperature cycle with sample material up to one hundred times. Reagents are added to the sample material, which leads to a doubling of the DNA strands to be diagnosed with each cycle. The DNA material can then be detected in this much higher concentration.

PCR-cyclers usually use Peltier elements, which are comparable to the design of thermoelectric half-Heusler modules, but with completely different materials and under completely different conditions. Semiconductors made of the metals bismuth and tellurium are used, which have their optimal range of application in the temperature range from -40°C to 200°C. With a Peltier module, an electric current is impressed into the module, which creates a heat flow and leads to a cold and a warm module side.

Currently, discussions are being held with many potential customers who require fast and precise temperature control in the medical engineering sector. The applications are not limited to PCR cyclers, but rather many possible applications are being discussed. At present, all customer requirements and "customer pain points" are being compiled, and as a result we will design solutions that will benefit as many customers as possible. This project is being managed by Ms. Schmidt.

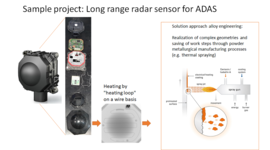

The "Alloy Engineering" project aims to address novel applications, such as three-dimensional heater structures, through additive manufacturing of our well-known resistance alloys.

In the past, we have already produced powders from our alloys, for example for thick-film pastes or for MIM (metal injection molding) components. Initial trials of 3D-printed Manganin structures have also been very successful.

The aim of this project is now to define a modular system of alloy powders and suitable additive manufacturing processes in order to be able to use them quickly in customer projects. Above all, however, it is a matter of identifying an initial area of application. Therefore, intensive customer interviews are also conducted in this project and the limits and weaknesses of today's solutions are precisely analyzed.

For example, radar sensors in automobiles, which are required for distance assistants, must be protected against icing during the winter. Today, heating wires are inserted into the plastic covers in a very complex process. It is necessary to find simpler and more cost-effective production methods for this purpose. These could be, for example, injection or printing processes of our alloys. This project is being managed by Mr. Achenbach.

The goal for both projects is to present solution concepts, which have already been technically and commercially evaluated, to management by next March. If the potential of these projects is sufficiently large, concrete product developments are then derived from them.

Dr. Jan Marien

Executive Vice President R&D

Michael Sting Assumes New Role as Business Development Manager

My name is Michael Sting and I’m 27 years old. I successfully completed my studies in Siegen as an industrial engineer specializing in mechanical engineering. For six years, I have now been working in the Alloys business unit. I was already involved in this company as an intern and working student and from the very beginning I was engaged in developing a pricing tool, preparing offers and conducting market research. In my last position in the field service, I was responsible for customers within Germany.

Since September, I have been responsible for business development topics in alloys sales. The experience I gained so far, especially the direct customer contact, has helped me to look at the big picture, analyze potential upstream and downstream applications and rethink processes together with the customer. These experiences were incredibly helpful in taking over my new responsibilities.

My tasks as a Business Development Manager are to identify new applications and products and, after appropriate market analysis, to introduce them into the innovation process. This includes, for example, material applications that have not been in focus up to now. In the following, I would like to give some examples of my tasks: As the latest innovation, the thermoelectric generator will be introduced as a new product and rolled out as a pilot project in Japan. Known alloys are being developed in new designs, such as brazing rings. ISA-CON® 450/550 is being developed as a pre-series product. The first samples are being taken for ISA-CON® 414. I also analyze the potential and feasibility of new alloys based on market changes and customer requests. Thus, I am also involved in the new innovation process, which is based on the process for idea management. This process is presented in a separate article.

Regarding my previous topics, the responsibility for the German market was divided as follows:

- North: Nils Achenbach

- East/southeast: Dora Kosiarska

- West: Christof Hild and Michael Sting

- Southwest: Michael Sting

Michael Sting

Business Development Manager