When developing individual solutions, customers may benefit from our long-standing experience. We offer the ideal solution for every application, because we use 3D CAD/CAE-based design as well as the latest technologies and processes.

Isabellenhütte has created a portfolio of standard products aligned with market requirements by using the expertise it has built up by developing precision measurement technology.

These standard solutions can also be adapted to customer requirements to varying degrees of freedom. The prerequisite is a corresponding project volume and the willingness to assume tooling and development costs.

The development department offers long-standing expertise in the creation of customer-specific products while taking corresponding standards and norms into consideration, both for industrial and automotive applications.

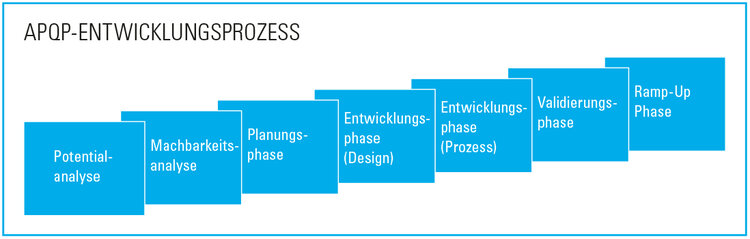

Every product development is based on a product development process according to IATF 16949 and undergoes several phases of development.

1. Potential analysis

2. Feasibility analysis

3. Planning stage

4. Development stage (design)

5. Develoment stage (process)

6. Validation stage

7. Ramp-up stage

Over the years, the development team of precision measurement technology has developed core competences in product design in line with customer requirements, project planning and project controlling, hardware and software design as well as product validation according to international standards and customer standards.

The development, adaptation and optimization of complex automated production processes is of particular importance to the production location of Germany.

The software SolidWorks is used for computer-assisted mechanical design at Isabellenhütte. Thanks to the support of various file formats, we can import the design specifications and information about the installation conditions of our customers and take these into consideration in the design of the solution specifically made for them.

Furthermore, we are of course able to share the design data with them in various formats or create 3D drawings.

We use the tool AltiumDesigner to create the module circuit diagram and the circuit board layout. Thanks to the format compatibility, SolidWorks can be used to import the electronic modules into the overall design as a 3D model.

During the concept and design phases of new products, we are able to use the tools Ansys Maxwell and Comsol Multi Physics to implement extensive simulations and thus make design optimizations in short development loops.

Internal and external laboratories for development-accompanying investigations are available to developers for the product development.

In addition to various measuring devices and powerful analysis equipment, the laboratory for developing measurement technology has several calibration stands for DC up to 800 A and direct current voltage up to 1,200 V, system test stands, temperature chambers, a 4 kA direct current source and a test stand for ESD and cable-bound EMC tests.

Furthermore Isabellenhütte's environmental laboratory is equipped with temperature shock furnaces, high-current sources and various temperature and climate chambers where the samples can always be continuously monitored and loaded.

The company Isabellenhütte has a DAkkS-accredited laboratory for the measurement variables of direct current voltage, direct current and DC resistance as well as various thermodynamic measured variables.

Shunt Geometry

Customers of precision measurement technology can also benefit from Isabellenhütte's expertise in the well-established business field of precision measurement resistors, such as the fact that their busbar can be replaced directly 1:1 with the shunt with an integrated measurement technology solution.

We are able to develop the best possible solution for their application due to the 3D-CAT-based design.

Housing

The customer-specific requirements have already been met with the most diverse housing concepts in the field of measurement sensors.

The processes from the simple formalcoating of the PCBA to a vacuum encapsulation to the thermosetting injection molding have all already been successfully implemented in the precision measurement technology.

The IP protection class of the respective customer requirement can be flexibly responded to in this way.

Firmware

With the DC sensors with an integrated micro-controller, the precision measurement technology is based on the standard CAN 2.0 with 11 or 29 BiT identifiers. Many of these are already in field use and perform their work competently.

The use of a CANopen STACK has also already been implemented and is therefore not a stranger in the development of precision measurement technology.

PCBA-Design

Precision measurement technology leaves the production of PCBAs to the experts in this field. The design of the populated boards, however, is based entirely on the expertise of Isabellenhütte.

The design of the sense grips require special experience, especially with fast-changing currents. The integration of the ICs introduced into the product development by the customer, such as a pre-charging circuit, has already been successfully implemented.