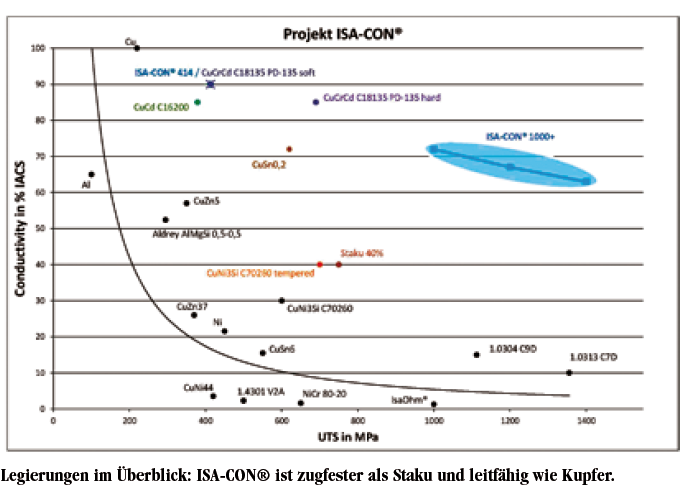

Copper is frequently used as an electrical conductor. However, the low tensile strength and mechanical hardness as well as the restricted bending changeability are its disadvantages.

This hurdle has been overcome by the new alloy ISA-CON® from Isabellenhütte. The copper-based alloy produced as wires combines high electrical conductivity with high strength.

Absorb High Tensile Loads

The two material types ISA-CON®414 and ISA-CON®1000 are the focus of the new product series. With a minimum tensile strength of 414 and 1000 MPa, they have a significantly higher tensile strength than copper at 200 Mpa.

The minimum tensile strength of ISA-CON®1000 is even well above that of copper-clad stainless steel, called Staku, at 700 MPa.

Good Electrical Conductivity

The other important property is electrical conductivity: With 90% IACS in the annealed state, ISA-CON®414 comes very close to copper. With 60% IACS, high-strength material ISA-CON®1000 is also well above the widely used Staku wires at 40% IACS.

Avoid Cadmium

The material ISA-CON®414 is an RoHS-compliant material, which can replace similar materials that contain cadmium. The high-strength material ISA-CON®1000contains the alloying elements silver and zirconium. Both wires are not only able to elastically absorb high tensile loads and be optimally conductive. They also offer a high hardness, are corrosion-resistant and retain their properties, even at higher temperatures over long periods of use.

Typical Application Areas

Signal and overhead lines for railways and automotive cables are typical areas where ISA-CON® can be used. The increasingly important areas of energy supply, generation, management and data transmission also offer various application opportunities.

Characteristics

The individual properties can be looked up in the various data sheets.

Delivery Form

ISA-CON® is delivered in the form of round and flat wires.

Other dimensions are available by request.