Global climate change, the rising amount of CO² in the earth's atmosphere and the decline of fossil fuels are the driving forces behind the development of new technologies, which make combustion systems more efficient and thus allow for CO² and fuel savings.

The thermogenerator is a technology currently being developed by Isabellenhütte that promises this increase in efficiency.

What is a thermogenerator?

The thermogenerator is an assembly that allows for the direct conversion of waste heat into electrical current. The main advantage of this technology compared to conventional systems i the high longevity and ease of maintenance, which results in the thermogenerator not requiring any moving components for the conversion.

The thermogenerator is used for the so-called energy harvesting where unused waste heat from energy-rich processes is harvested, converted into electrical current and thus made usable again.

The system for energy recovery can be divided into three areas

- The thermoelectric material

- The thermoelectric module

- The thermogenerator (system)

How do thermoelectric materials work?

The energy conversion occurs in the smallest unit of the thermogenerator: in the thermoelectric material.

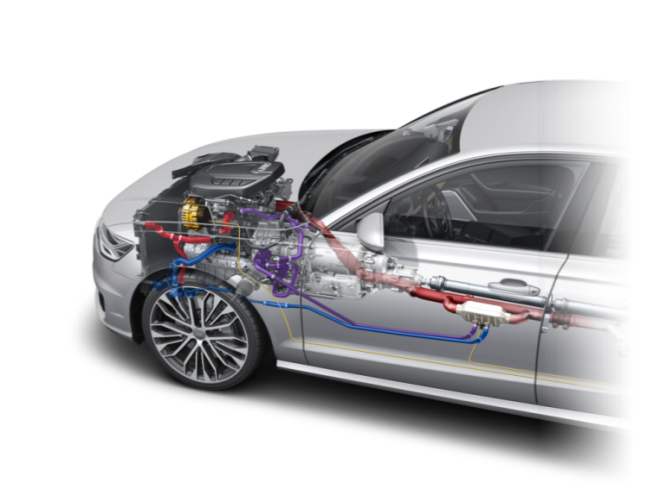

Thermoelectric materials are solids that convert heat into electricity under certain geometric and thermal conditions. They utilize the Seebeck effect (discovered in 1821), which describes the behavior of electrically conductive and thermally resistant materials that are exposed to a temperature gradient.

If there is a high temperature on one side of the columnar material and a low temperature on the other side, electrons diffuse from one side of the material to the other. In the process, the diffusion process creates an electric voltage within this material. A high thermal resistance must be present in order to achieve the greatest possible voltage output.

To date different material classes have been researched, which meet these material properties. The material classes of the half-Heusler alloys (ZrHf; SbSn); tellurides (Bi2Te3; PbTe), silicides (SiGe) and Skutterudite (CoSb3) turned out to be particularly powerful "thermoelectrics."

The performance of a thermoelectric material is expressed via the so-called thermoelectric grading factor ZT and significantly determines the efficiency of the technology.

What is a thermoelectric module?

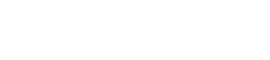

Many cubes of thermoelectric material are combined with each other in the thermoelectric module and arranged so that they are thermally parallel and electrically connected in a row. Two differently doped elements of the material are combined with each other via conductive contact bridges. This is also called a pair of legs (unicouple).

In the n-doped material, electrons diffuse from the hot side to the cold side, and in the p-doped material electrons diffuse from the hot side to the cold side. If the first and last link of the electrical series connection are connected to a consumer, an electrically closed circuit is achieved.

An insulating layer (ceramic for example) is applied in order to protect this circuit against electric short circuits on the hot and cold side of the module. This must ensure a good heat transfer despite the electrical insulation.

A major challenge in the production of thermoelectric modules is the tremendously high material load caused by the temperature difference.

What is a thermogenerator?

A thermogenerator system includes all components that are required to supply the module with heat on the hot side of the module, to dissipate heat on the cold side and to make the generated electrical current usable.

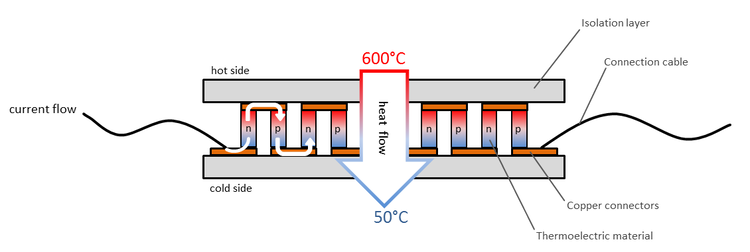

On the one hand, this includes a heat exchanger that absorbs the heat from an existing system (such as the waste heat of a passenger car) and transports it to the hot side of the thermoelectric module.

On the other side of the module, there is also a heat exchanger through which the modules are actively or passively cooled (via air or a liquid cooling medium). Additional high-temperature resistant cables and plugs are required so that the thermogenerator can be electrically connected.

Heat exchangers, modules and connecting cables are protected by housing in order to protect the modules from oxidation by aggressive gases.

The intensity of the direct current that is produced by the modules changes simultaneously with the intensity of the energy from the heat source. Depending on the application, this direct current must be transformed via a converter into a constant direct current or into alternating current.

This requires a customer-specific power electronics unit.

Where is the thermogenerator used?

A thermogenerator is used everywhere that energy is lost unused in the form of heat. On the one hand, this includes passenger cars and trucks, since about 30% of the energy available here is lost by the exhaust gas system. The thermogenerator is placed in the exhaust gas system where it absorbs the hot exhaust gases and converts them into electricity.

This electric current can be fed back into the car's on-board electrical system, thus relieving the on-board electrical system generator. This results in a higher utilization of the combustion process, which can save fuel and CO².

Isabellenhuette Heusler GmbH & Co. KG is currently testing the economic integration of a thermogenerator in vehicles as part of the EU funding projects "INTEGRAL" and "thermoHEUSLER²."

Other possible application areas are the energy improvement of CHP plants or the waste heat transfer of annealing and melting processes.