What characterizes a good thermoelectric material?

A thermogenerator extracts a heat from a heat source, such as the exhaust gas from a passenger car, and converts part of this heat into electric energy.

The thermoelectric material contained in the thermogenerator is responsible for this conversion process. The better the thermoelectric material, the more heat can be converted into electric energy. This is called a high conversion efficiency.

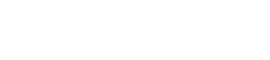

In addition to the temperatures on the hot and cold side of the thermogenerator, the conversion efficiency depends on the so-called thermoelectric quality figure ZT. The ZT was described by Edmund Altenkirch for the first time in 1909 and is calculated from the electrical conductivity, the thermal conductivity and the Seebeck coefficient (thermal stress) of a material.

It can be seen from equation 1 that a good thermoelectric material is characterized by the highest possible electrical conductivity and a high Seebeck coefficient with low thermal conductivity.

Half-Heusler - what is that?

In 1901, Dr. Friedrich Heusler discovered a new material class at Isabellenhütte. He produced alloy samples from the three non-magnetic metals of copper, manganese and aluminum. He noticed that the alloy made of two parts copper and one part each of manganese and aluminum had strong ferromagnetic properties.

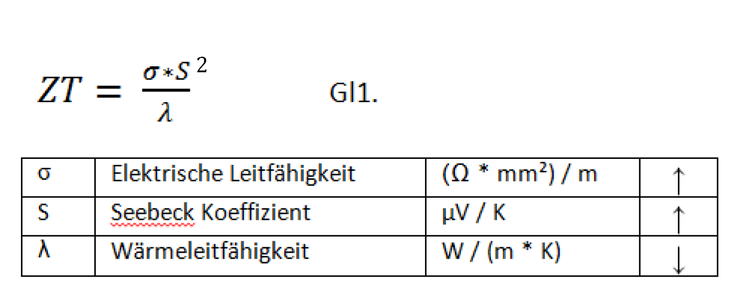

This discovery was a small scientific sensation and at first could not be explained with the knowledge of physics at the time. On closer investigation, it was later discovered that this particular alloy forms a crystal structure that was unknown until then. The name Heusler structure was given in honor of its discoverer. Today, many materials are known with a Heusler structure. They are generally referred to as Heusler alloys or Heusler compounds.

The so-called half-Heusler alloys are closely related to the Heusler alloys. Figure 1 shows the two structures in comparison. Some grid spaces remain unoccupied with half-Heusler compounds. The interesting thing about half-Heusler alloys it that the different grid spaces can be occupied with different metals.

Thus the elements shown in green in figure 2 can be placed on the green grid spaces, the blue elements can be placed on the blue grid spaces and so on. In addition, elements can be mixed within the individual colored groups. In this way, less nickel can be added at the red position, for example, and copper can be added to make up for this proportion. This results in countless possible material combinations with always different physical properties. It is thus easily possible to design an N and P-conducting thermoelectric half-Heusler material.

Why Half-Heusler as a thermoelectric material?

Thermoelectric materials can be roughly divided into the groups of low, high and maximum temperature materials according to their application temperatures.

Half-Heusler materials belong to the high temperature materials. Their optimal application range is between 400°C and 600°C. However, half-Heusler materials do not have the highest ZT value or efficiency compared to other high temperature materials like Skutterudites, but they do have a good property mix.

Suitability as thermoelectric material is not only determined by a high conversion efficiency and good ZT grading factor. Other properties that make up a usable material are just as important. These include good mechanical properties and a high long-term stability as well as material costs and the non-toxicity of the elements contained.

Since two materials are always required to built thermogenerators with P and N-conductors, virtually identical expansion coefficients of these two materials are also vital. Figure 2 compares different high temperature materials qualitatively based on their properties.

Properties of different high temperature materials by comparison

| Material class | ZT value | Cost per KG | ROHS conformity | Mechanical strength |

| Half Heusler | + | O (+ for Hf-free) | + | ++ |

| Skutterudite | ++ | + | + | O |

| Silicides | + | ++ | ++ | + |

| Leadtelluride | ++ | O | -- | + |